How to scrap industrial machinery?

How to scrap industrial machinery?

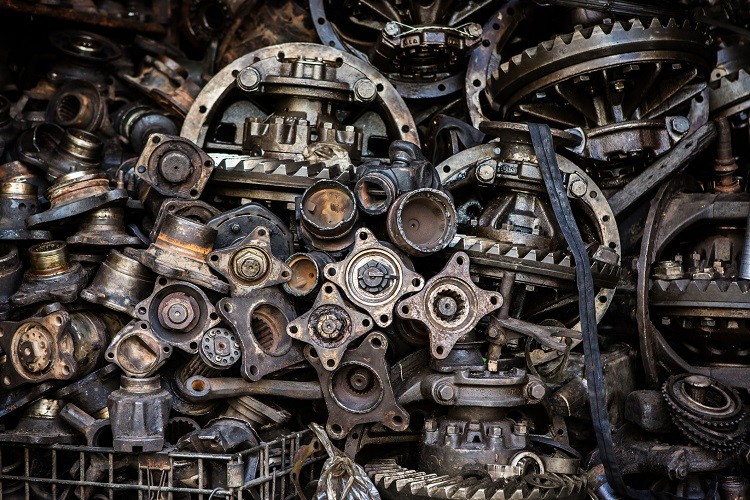

In the case of passenger cars, once they are no longer economically viable, there is no problem as to what to do with them. They are scrapped, dismantling the more valuable parts if possible, in order to make at least some funds for the disposal of the vehicle. But what if a similar problem arises with industrial machinery? How do you dispose of production lines in compliance with occupational health and safety rules?

Why is industrial machinery being scrapped?

Like any device or item of equipment, an industrial machine has a limited lifespan and continued use may end in disaster. This is true of any type of hydraulic, electronic or mechanical equipment, and the time when they refuse to operate depends on how often they are used, how they are maintained and how well they are serviced. Scrapping is necessary when it is determined that the cost of repair will far outweigh the purchase of new equipment, the machinery you own is outdated and increasingly inefficient. The reason for the decision to dispose of industrial machinery is often the difficulty of selling it. It is extremely important to entrust the dismantling and scrapping operations to a suitable operator.

What is the scrapping of industrial machinery?

In accordance with current environmental and occupational health and safety legislation, any machinery disposal must be carried out in accordance with a pre-established action plan defining exactly how and where harmful and hazardous substances are to be stored. Entrusting these operations to a suitable, experienced company solves the problem of relocating machinery, which is often not only heavy, but also of unusual, irregular shape, so that its transport requires appropriate preparation and equipment. The time taken to carry out the work of dismantling machinery and entire process lines depends on the level of complexity of their construction and the appropriate preparation of the technical team.